HumiSonic

The new humiSonic range comprises two versions, meeting the needs of all applications: humiSonic compact, small enough to be installed on a fan coil, and humiSonic direct, for room distribution.

Ultrasonic humidifiers feature a small water storage tank and piezoelectric transducers installed at the bottom of the tank. The surface of the transducer vibrates at very high speed (1.65 million times a second), a speed that does not allow the water to move due to its inertial mass. During the negative amplitude of the transducer cycle, a sudden void is created that brings about the production of microscopic bubbles, which are pushed to the surface of the water during the positive amplitude of the cycle. This effect is called cavitation.

During this process, the resulting intersecting sound waves created directly underneath the surface of the water cause very small droplets of water to separate, forming a fine mist of vapour that is immediately absorbed by the flow of air.

Features:

- efficient, as ultrasonic humidifiers guarantee energy savings of 90% when compared to ordinary steam generators;

- reliable, as humiSonic is guaranteed for 10,000 operating hours when running on demineralised water;

- precision: relative humidity control of ±1% on the set point;

- absorption efficiency: the droplets, just 1 µm in size, evaporate instantly;

- easy installation: in the basic configuration, humiSonic is a plug & play solution;

- maximum hygiene: no water recirculation and periodical washing cycles.

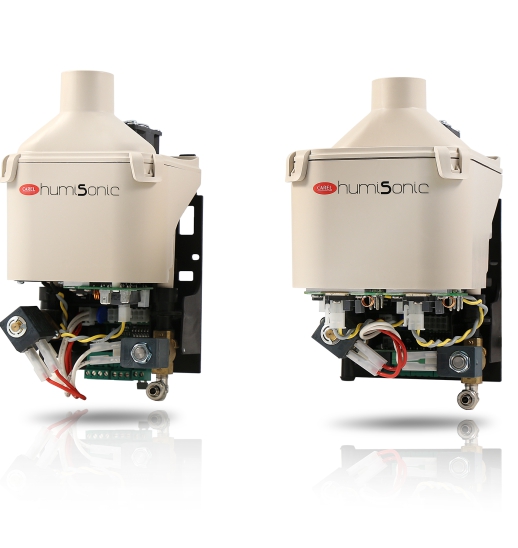

humiSonic compact

humiSonic Compact humidifiers are smallest humidifiers of Ultrasonic humidifiers family.

This product is available in two sizes: the 0.5 l/h version, whose compact size makes it ideal for installation on fan coils, and the 1.0 l/h version, ideal for more general applications. The built-in electronic board ensures precise control of unit operation and humidity production, with a complete and intuitive user interface.

humiSonic direct

The features of the new humiSonic direct highlight its versatility and make it suitable for every type of application: datacenters, museums, offices, printing facilities and cold stores are some of the typical uses, thanks to its compactness and efficiency.

For example, a humiSonic direct humidifier installed in the hot aisle of a datacenters eliminates the need for steam humidifiers in the CCU, simplifying the system and guaranteeing a very fast return on investment, due to the 90% lower running costs.

humiSonic direct encompasses, in one single solution, the control panel/power supply and air humidity probe. It is therefore a fully stand-alone unit, ideal for both new applications and retrofit installations. In addition, main/secondary mode can be used to quadruple humidification system capacity.

humiSonic direct can be connected to a convenient remote display, so as to monitor the unit without needing to access the humidifier directly.

It can also be easily integrated into a BMS using an external signal (for example, 0 to 10 V, 4 to 20 mA) or via a serial link with Modbus protocol. If controlled by a sufficiently accurate external signal, humiSonic can achieve exceptional precision: even less than ±1% around the relative humidity set point.

The transducers that guarantee at least 10,000 continuous operating hours mean maintenance is needed so rarely as to be almost forgotten; humiSonic direct will remind users when maintenance is required

humiSonic ventilation

humiSonic for air handling units makes adiabatic humidification available to smaller ducting systems, offering a high energy efficiency alternative to steam humidification.

Energy consumption per kg of evaporated water is in fact 90% lower than with steam!

Installed directly in the air flow, humiSonic can atomise water into very small droplets (5 µm on average), which are instantly absorbed.

The new generation humiSonic embodies all the attention that CAREL has always paid to the hygiene of its humidification solutions. All components in contact with the water are made from stainless steel, and not water is left to stagnate in the main body at the end of the humidification cycle. In addition, the electronic controller manages periodical washing cycles when the system is not running.

These hygiene features, together with the very high precision that humiSonic can achieve (±1% around the relative humidity set point), make it an ideal solution even for more critical and delicate applications, such as cleanrooms.

humiSonic for air handling units comprises two elements that make it a powerful and complete solution: the main body (containing the piezoelectric transducers) and the electrical power supply and control panel.